Overview#

Designed and manufactured a carbon/Kevlar hybrid laminate seatpost airfoil using vacuum-assisted resin transfer molding (VARTM)—executed entirely in my kitchen as a personal engineering challenge.

The Challenge#

Create a functional aerodynamic fairing for a bike seatpost that:

- Fits existing seatpost geometry precisely

- Uses proper composite manufacturing techniques

- Demonstrates hands-on composites experience

- Could be made with limited equipment

My Approach#

Phase 1: Design & Prototyping#

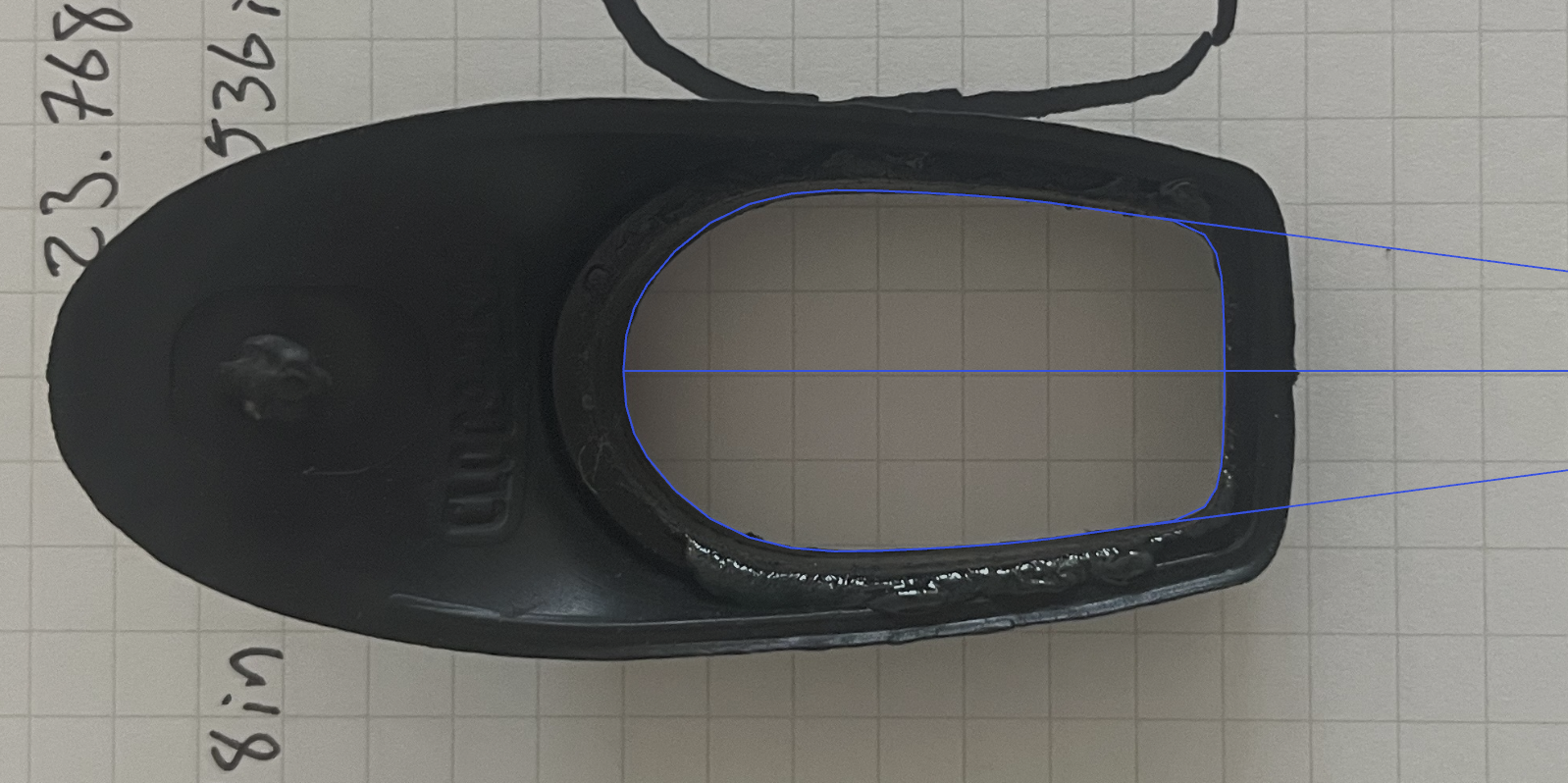

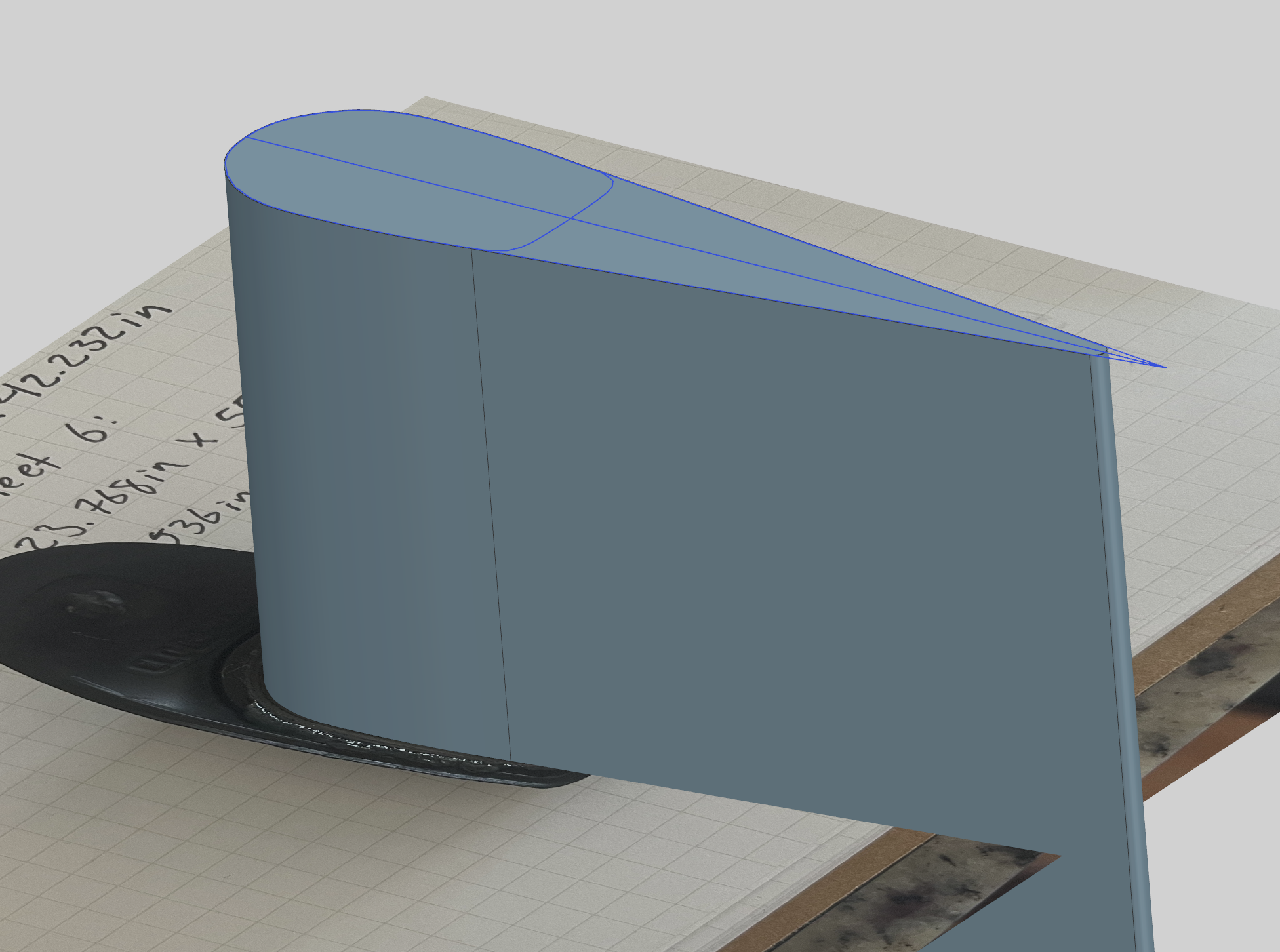

CAD model created from photo reference of the bike part, designing an airfoil profile to wrap around the existing seatpost.

Rapid FDM prototype to verify fitment before committing to composite manufacturing.

Phase 2: Mold & Layup Preparation#

- 3D printed mold overnight

- Prepped mold for layup at club workspace

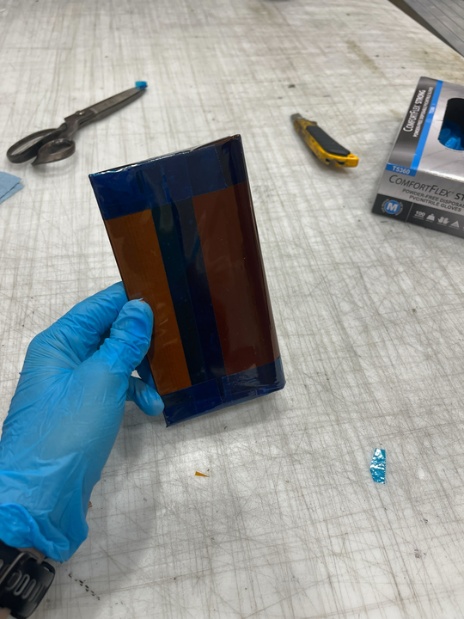

- Laid up carbon/Kevlar hybrid laminate using scrap material

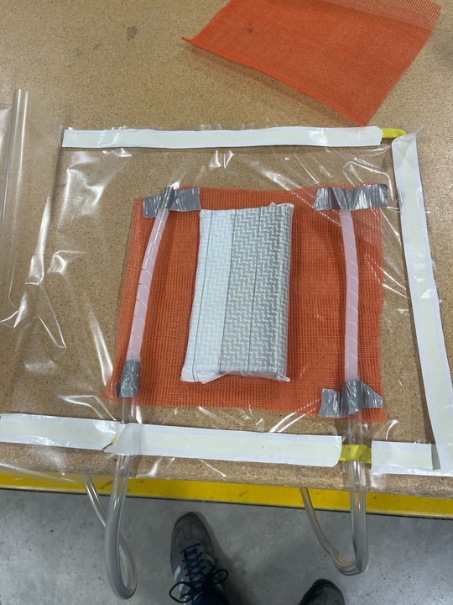

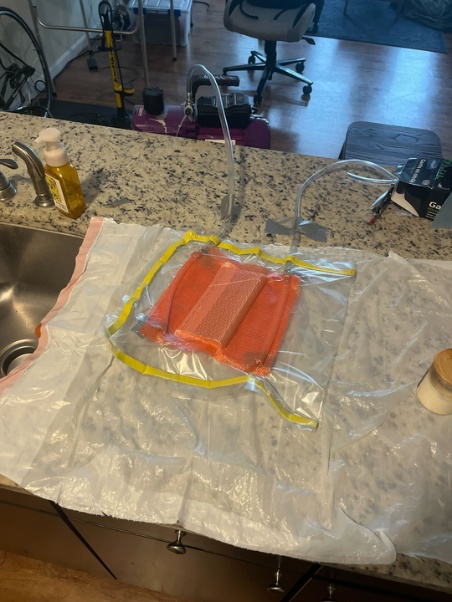

- Transported tools to kitchen for VARTM process

Phase 3: VARTM Resin Infusion#

The infusion process was performed twice. First attempt had dry spots due to insufficient resin pull-through—a valuable learning experience. Second attempt succeeded with proper technique.

Results#

- Fabricated functional composite part

- Excellent fitment thanks to accurate referencing

- Gained hands-on experience with VARTM process

- Learned troubleshooting for dry spots in infusion

Key Skills#

- Composites: VARTM Resin Infusion

- CAD: Part Design from Reference

- Manufacturing: 3D Printed Tooling, VARTM Composite Setup

- Problem Solving: Process Iteration, Manufacturing Failure Analysis

Note: Proper PPE was used throughout, and the kitchen was thoroughly cleaned afterwards.