Overview#

Designed and manufactured custom testing fixtures for Fermilab’s Silicon Detector (SiDet) Facility, enabling reliable thermal testing of sensors destined for CERN’s Large Hadron Collider upgrade.

The Challenge#

The existing test stand had critical issues:

- Sensor planks held by improvised file holders

- CO2 cooling lines were unstable, causing lateral movement and torsion

- Frequent damage to fragile adapters and expensive sensor planks

- No proper mounting for thermal imaging camera

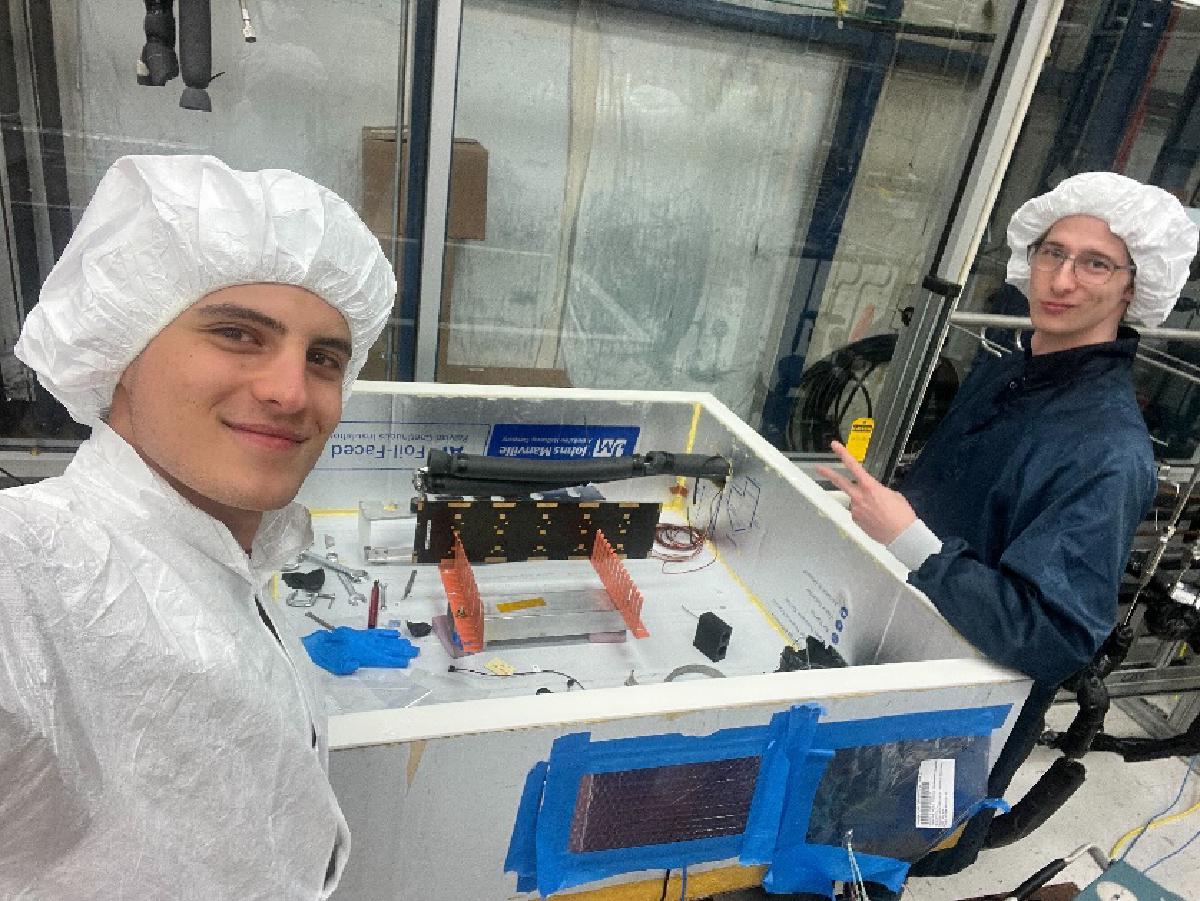

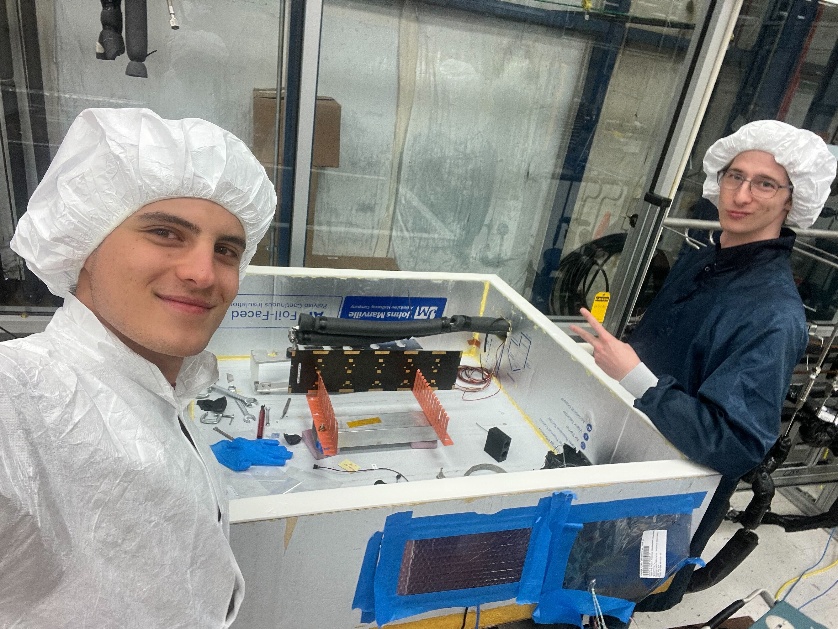

Me (left) with Post-doc Chris Cosby (right), who led the project for FNAL. The original setup shows the limitations we needed to solve. Poorly supported CO2 lines and repurposed file holders had a high rate of damage to the expensive prototype sensor frames

My Approach#

Same-Day Rapid Prototyping: All designs were created in CAD, 3D printed on-site, and installed the same day for immediate testing and iteration.

Solution 1: CO2 Line Stabilization System#

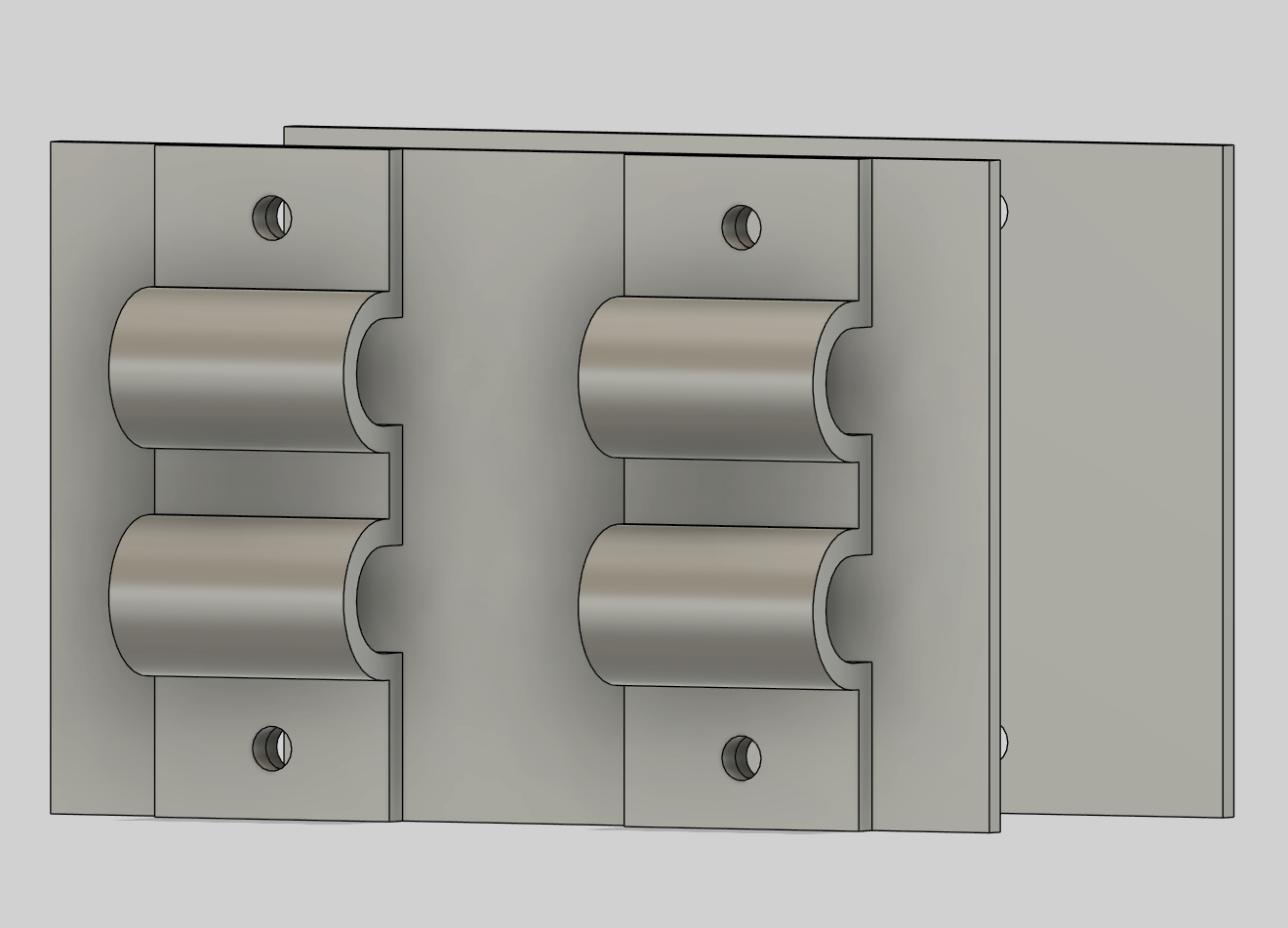

Designed a two-part mounting system that constrains CO2 lines from both lateral movement and torsion, protecting the fragile sensor connections.

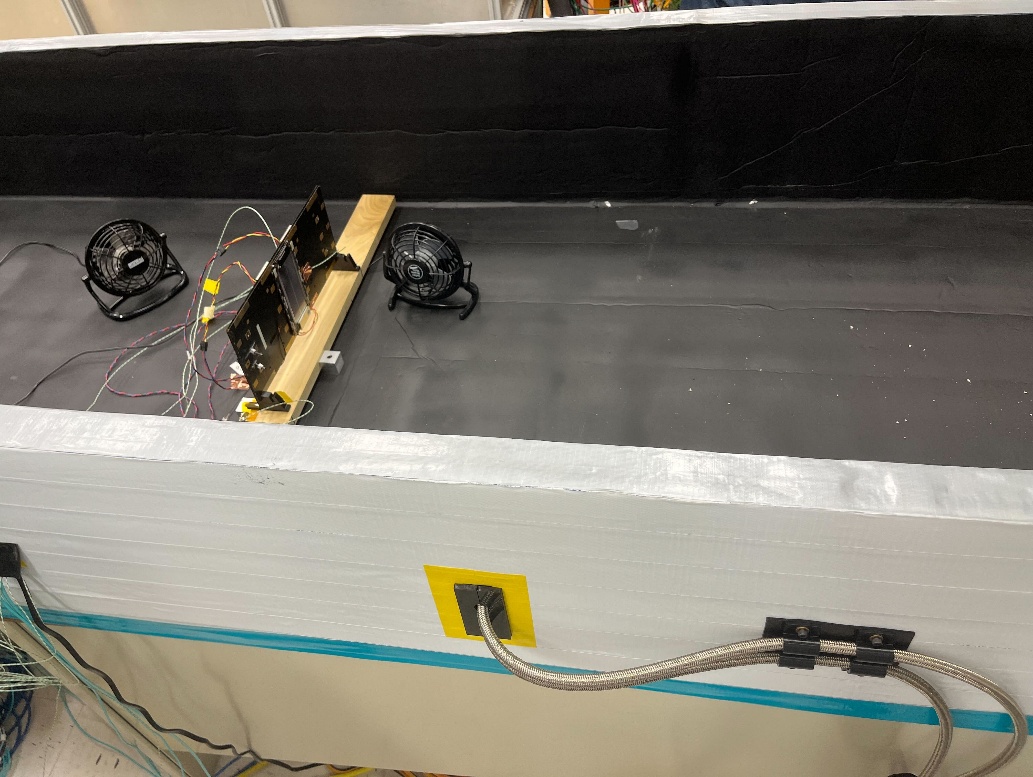

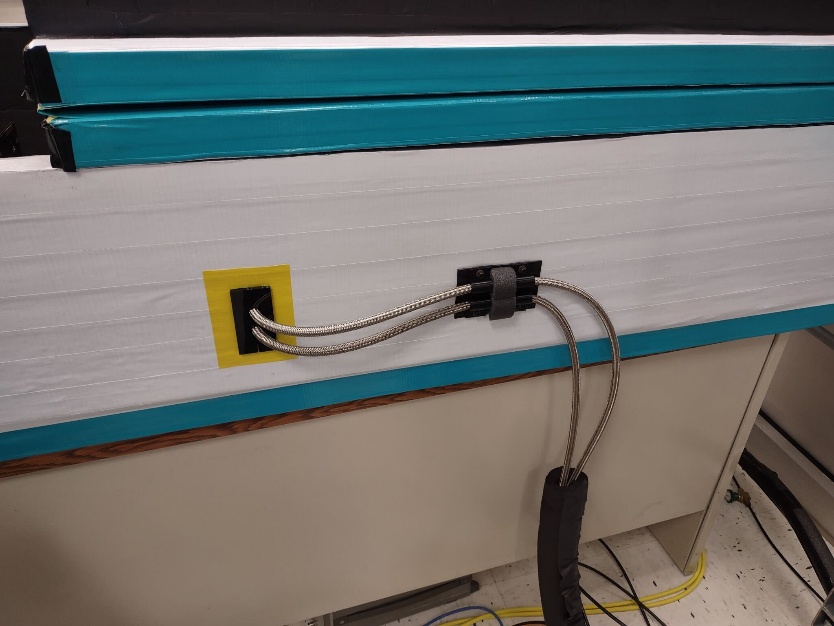

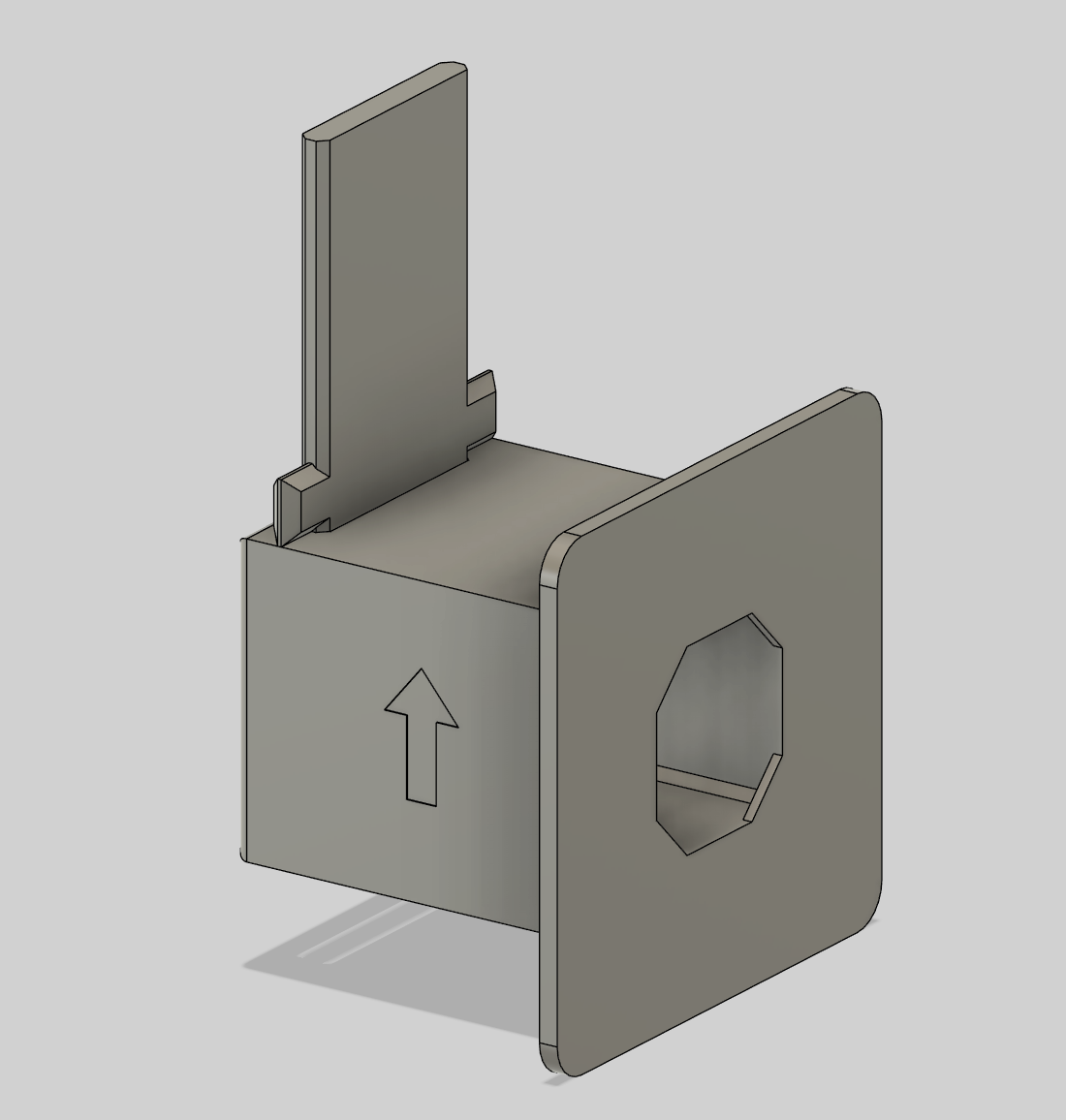

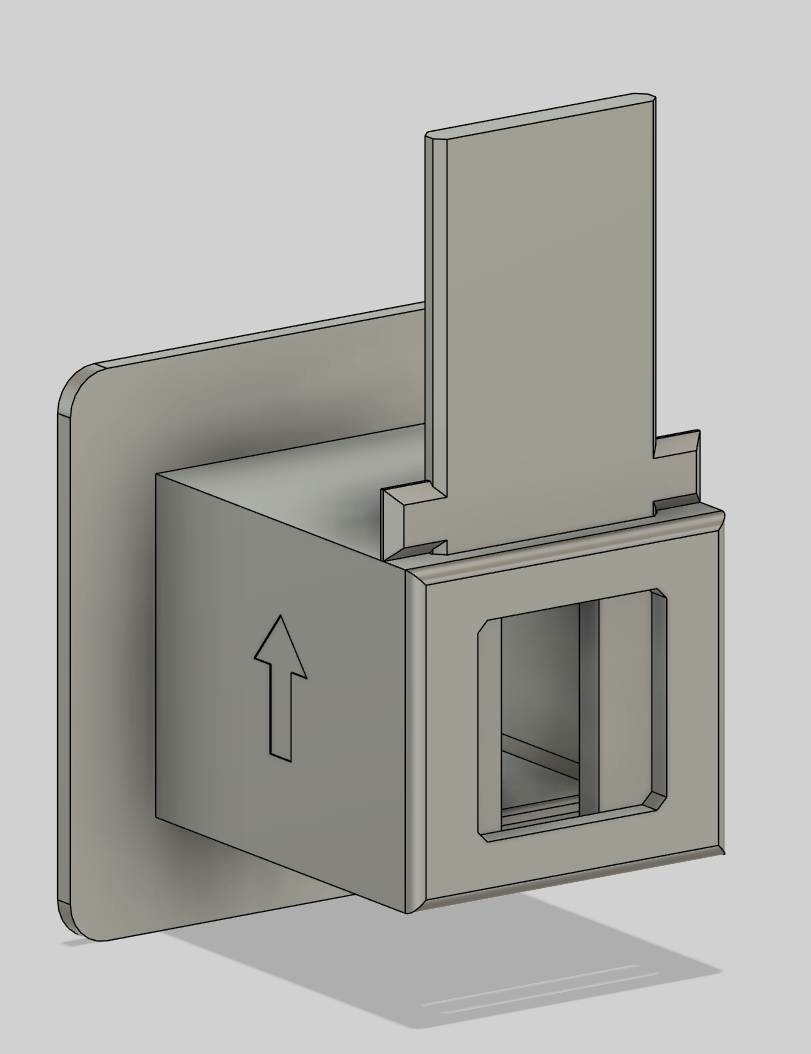

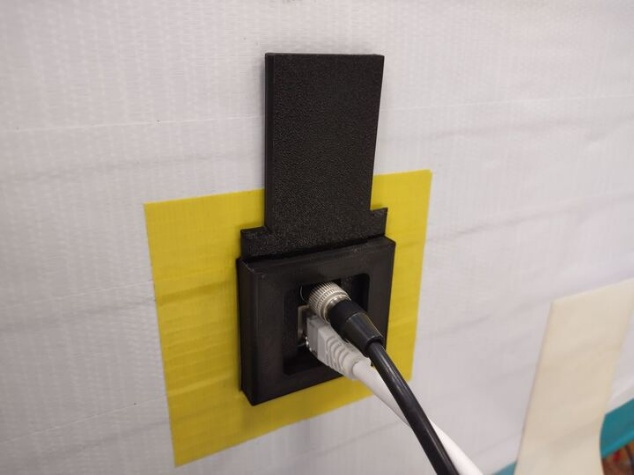

Box-CO2 line adapter and holder system. Combined with electrical tape for vibration isolation, these fixtures effectively isolate test planks from external forces. This is very important during the long imaging times from the thermal imaging stand.

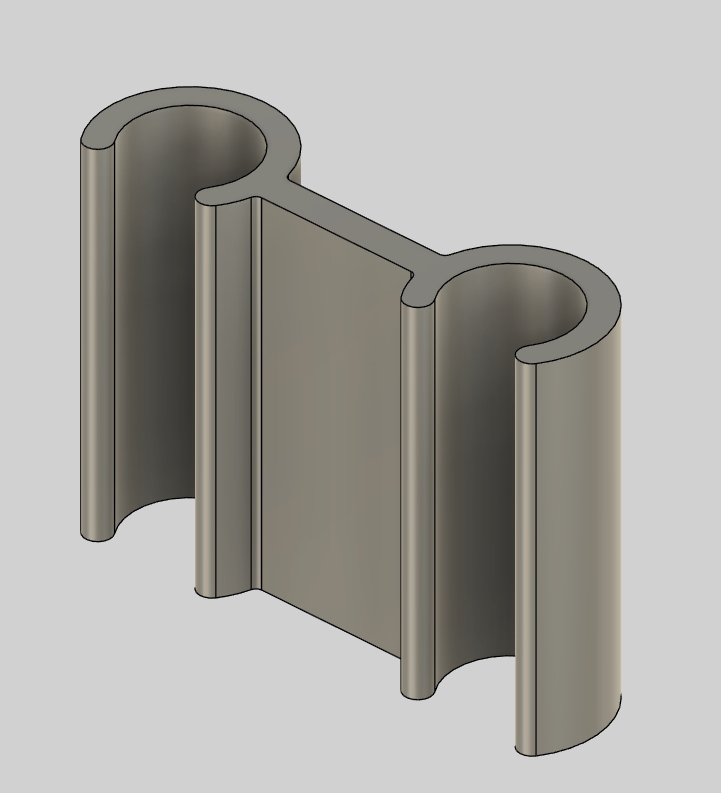

Simple compliant clip designed, printed, and installed in under 1 hour. Uses PETG flexibility for reliable friction fit. This piece held the CO2 lines right before the sensor as a final securement method.

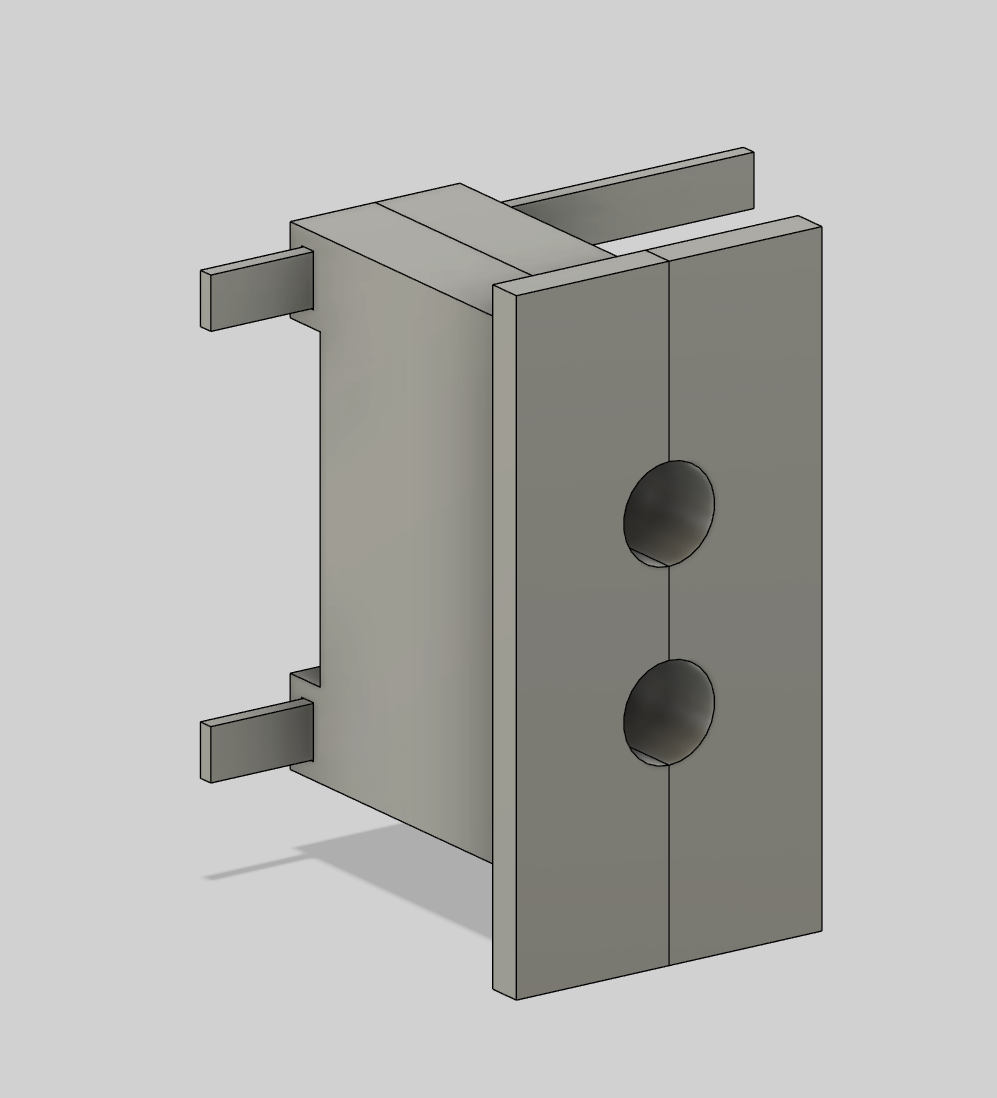

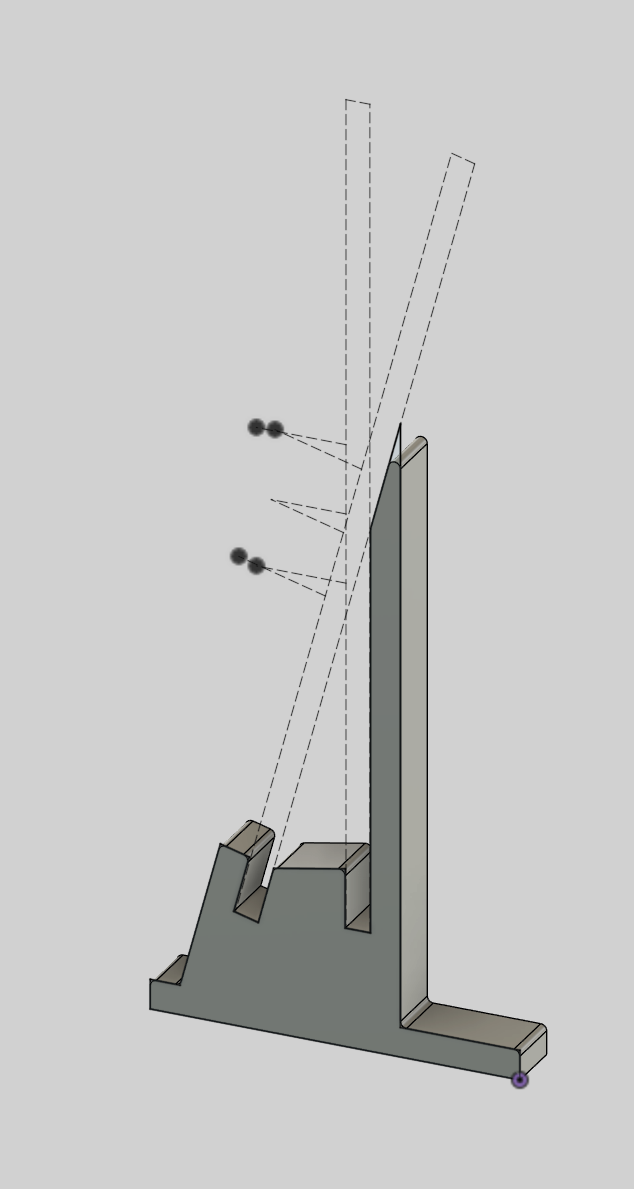

Solution 2: Dual-Position Sensor Plank Holder#

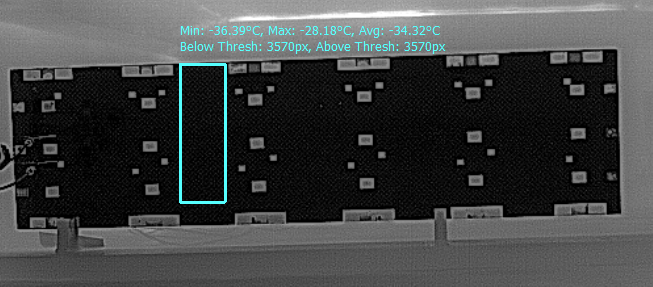

Custom holder accommodates sensors in two positions: one for CO2 line mounting, another for thermal imaging — without impacting line of sight of the important areas of the sensor.

Solution 3: Thermal Camera Mount#

Low-light passthrough insert for thermal the camera. Features tight tolerances to minimize light leakage, with a reversible back plate that closes the port when camera is not in use. This is important to help maintain the clean air environment inside the thermal imaging enclosure.

Results#

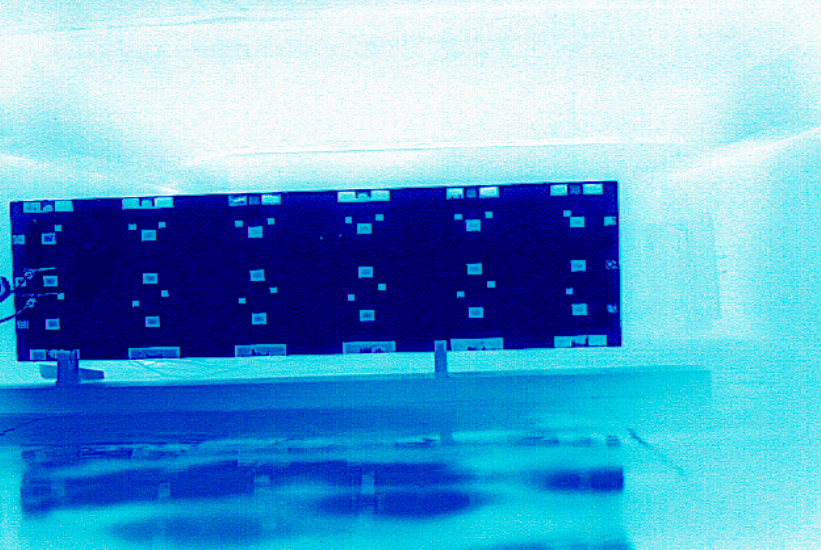

Thermal imaging results from successful tests. (Source: Chris Cosby, SiDet, Fermilab)

- Same-day turnaround from design to installed, tested parts

- Eliminated sensor damage from CO2 line movement

- Enabled repeatable, reliable thermal testing

- Fixtures continue to support ongoing LHC upgrade research

Key Skills#

- CAD: Rapid design iteration

- Manufacturing: FDM 3D Printing (PETG), Design for Compliance

- Engineering: Fixture Design, Vibration Isolation

- Environment: National Laboratory, Research Setting