Overview#

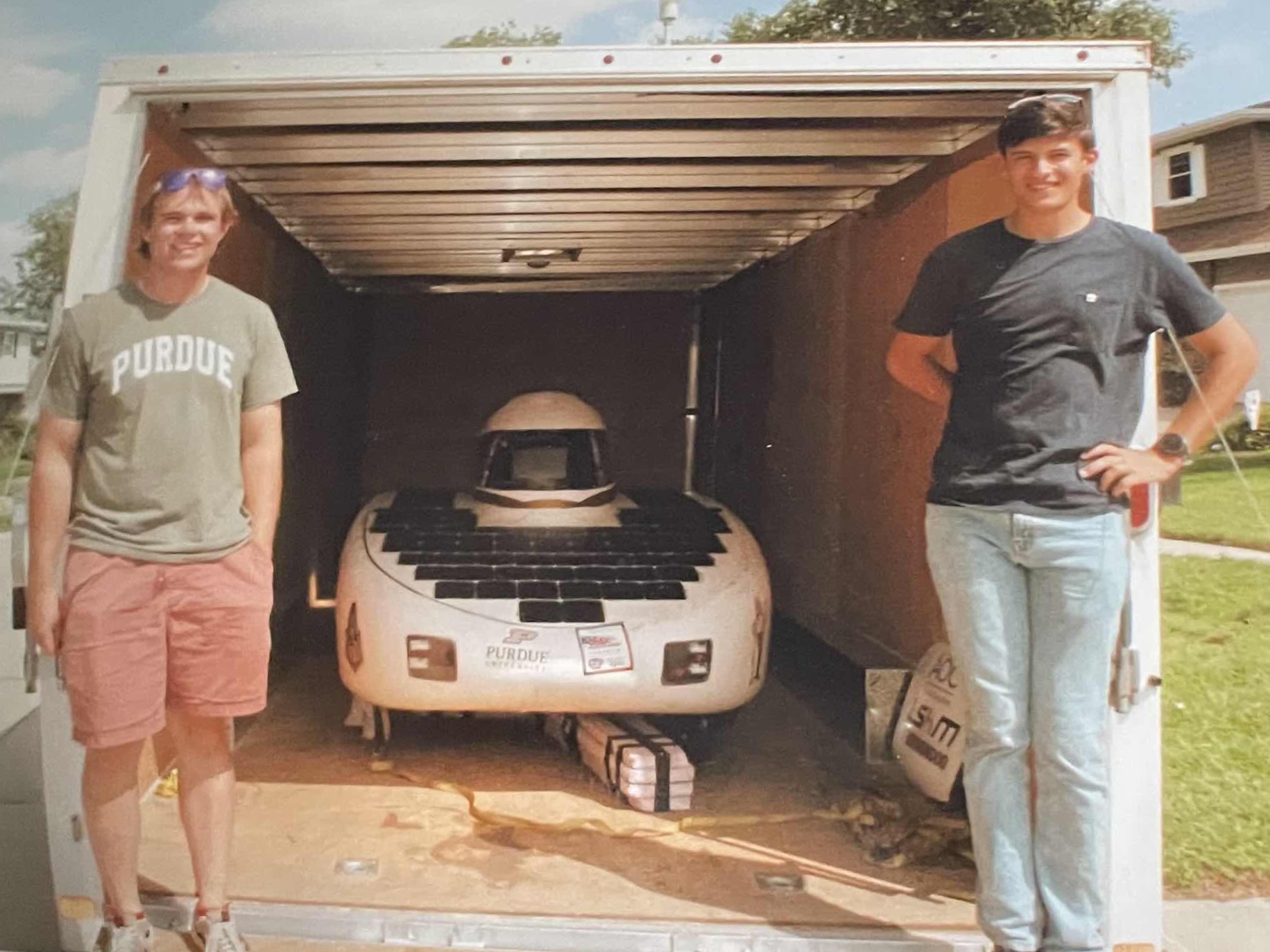

Designed the complete cooling system for Lux, Purdue Solar Racing’s competition solar car, taking the project from concept to race-ready installation over a 2-month design cycle.

The Challenge#

The solar car’s motor battery and BMS system required active cooling within extremely tight space constraints. Maintaining a low weight and low power consumption were the key driving ideas. The system needed to:

- Distribute airflow evenly across multiple cooling tubes

- Fit within the aerodynamic body shell

- Be manufacturable with available resources

- Survive race conditions and vibration

My Approach#

Phase 1: Concept Exploration#

Initial design inspired by automotive engine manifolds. This concept was scrapped after analysis showed uneven air distribution to the furthest tubes. Difference in air pressure among the tubes was found to be too large compared to the net static pressure in the system.

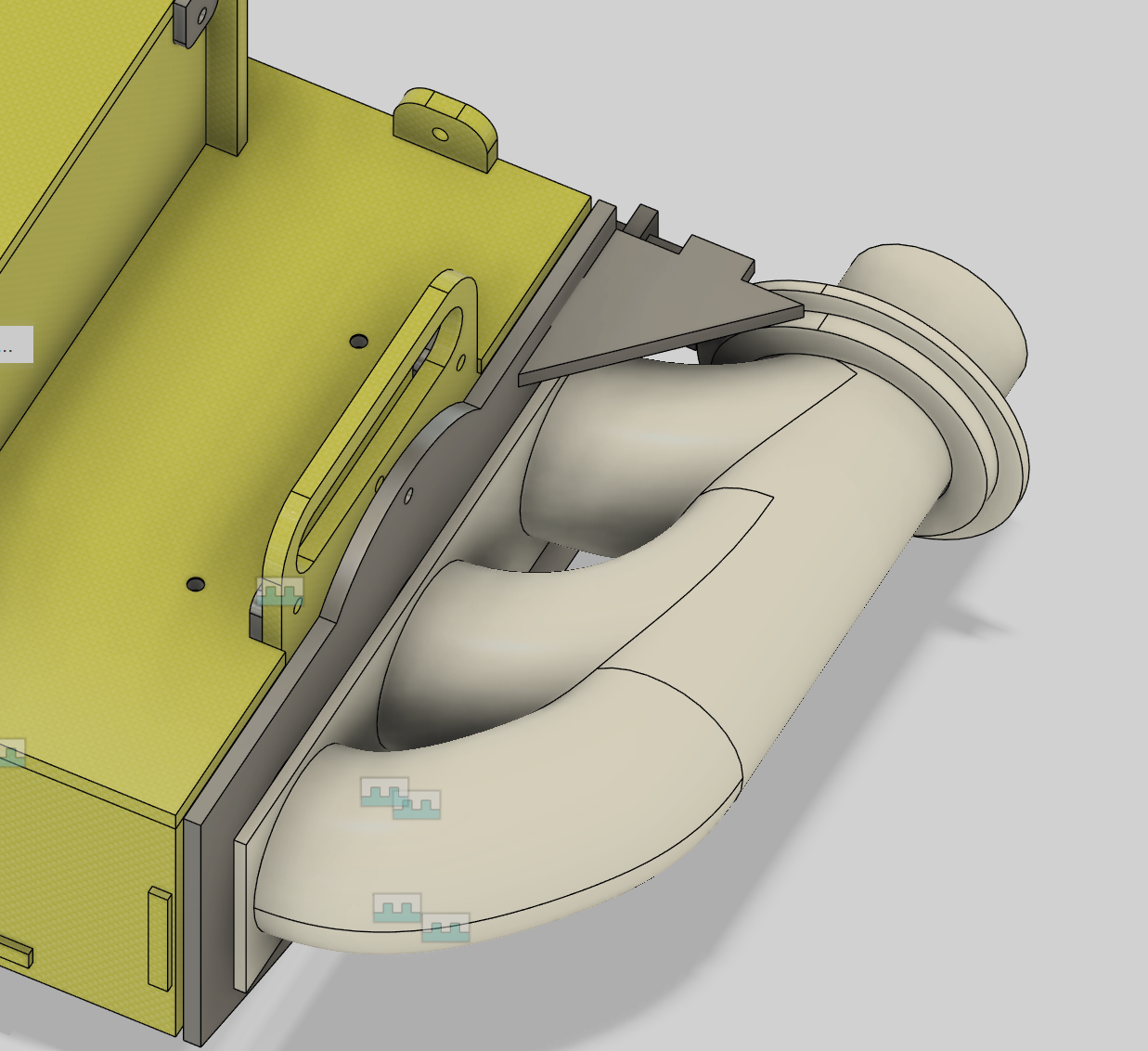

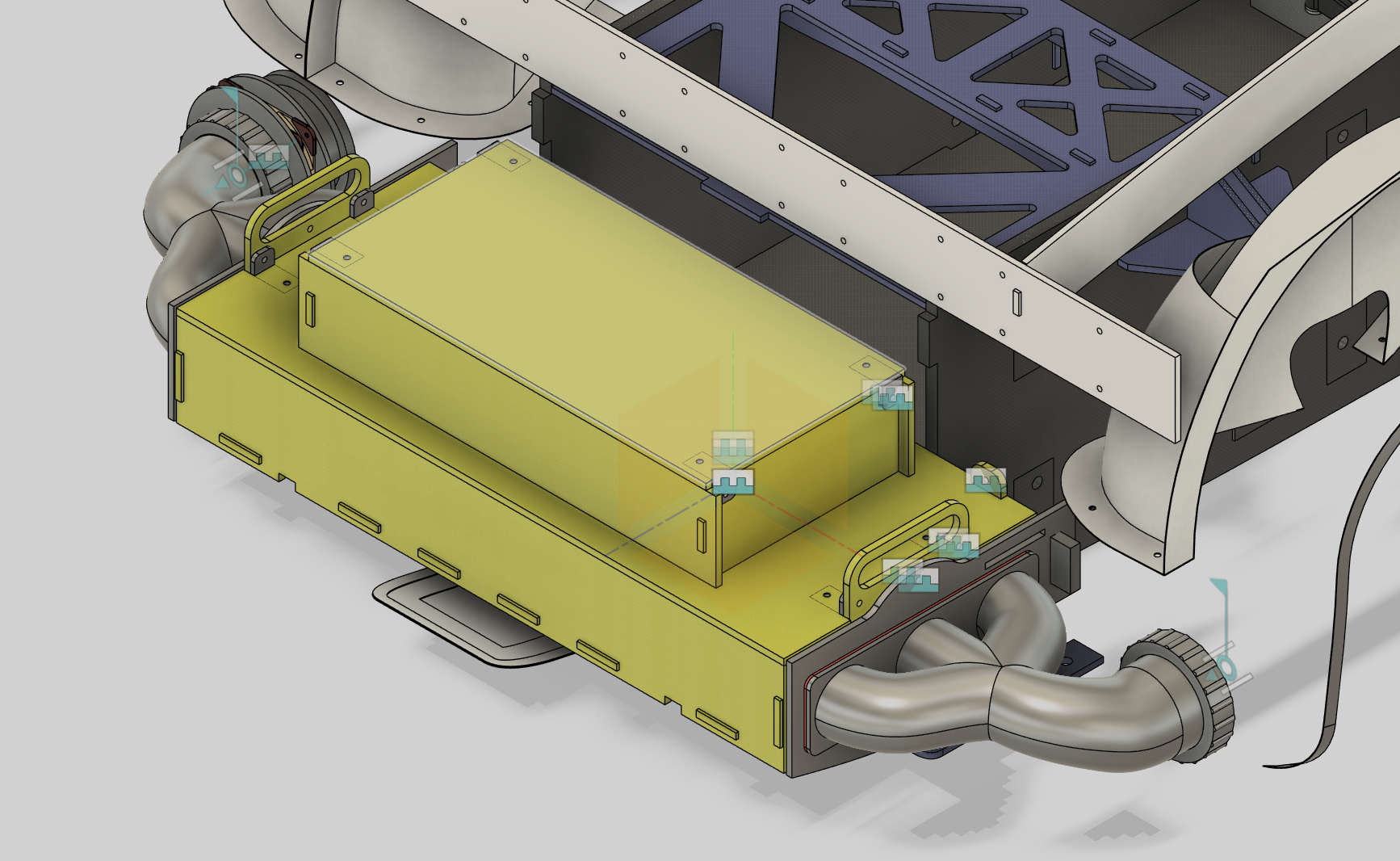

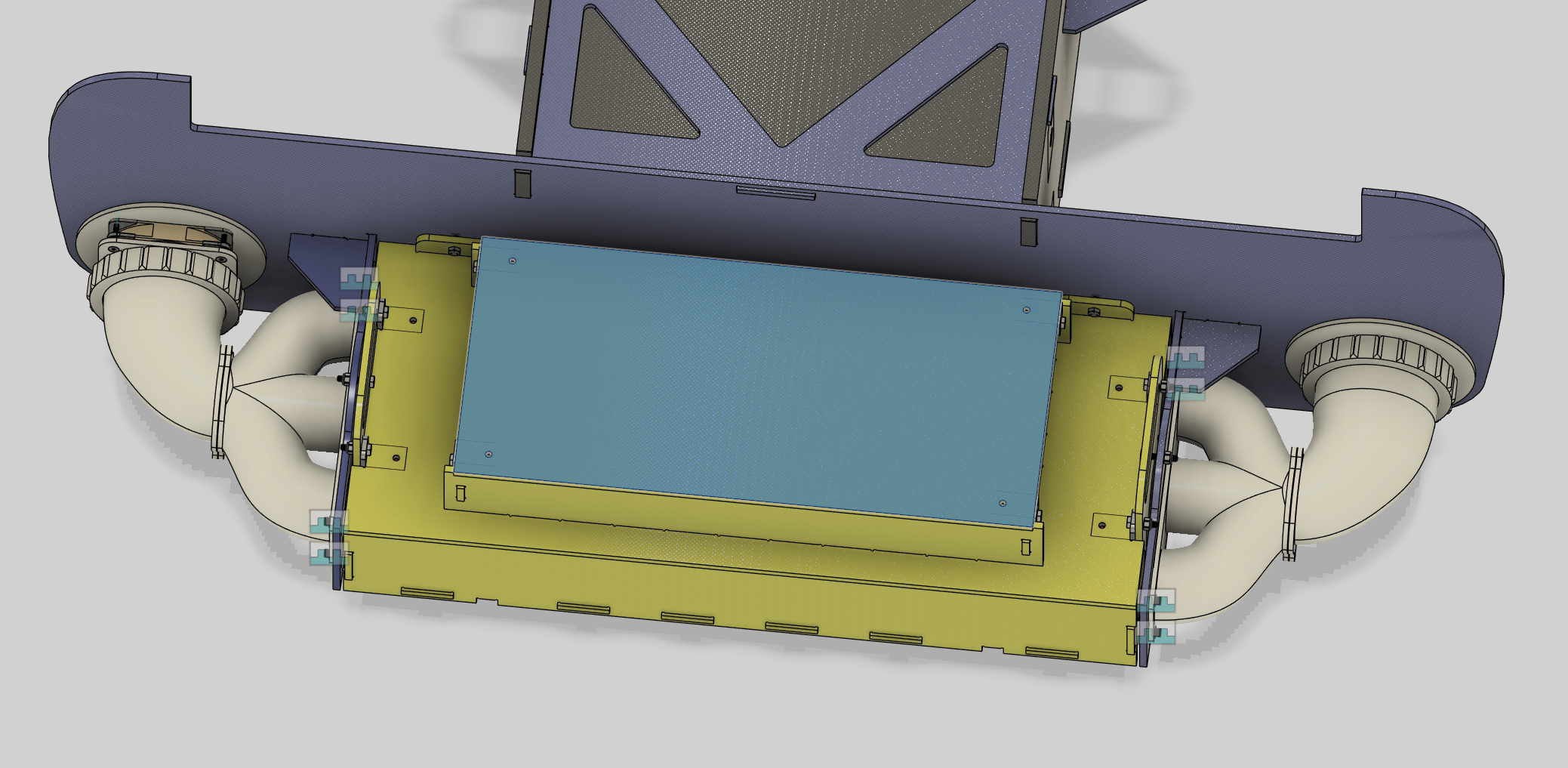

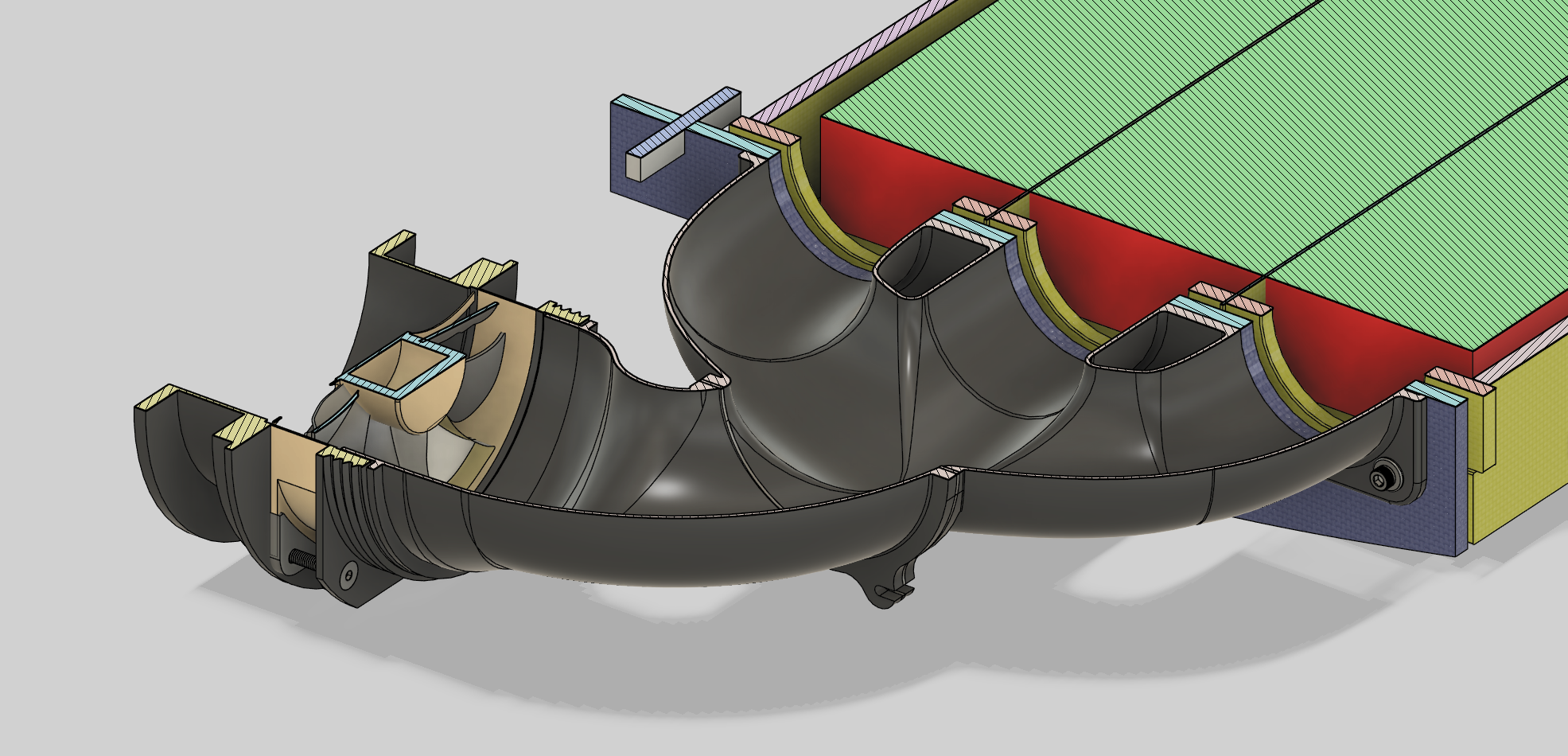

Phase 2: Trisplit Development#

Developed a trisplit architecture to improve flow distribution. Early versions prioritized function over manufacturability.

Refined surface modeling and split each side into multiple pieces for manufacturing. Added assembly considerations for in-vehicle installation.

Phase 3: Final Design#

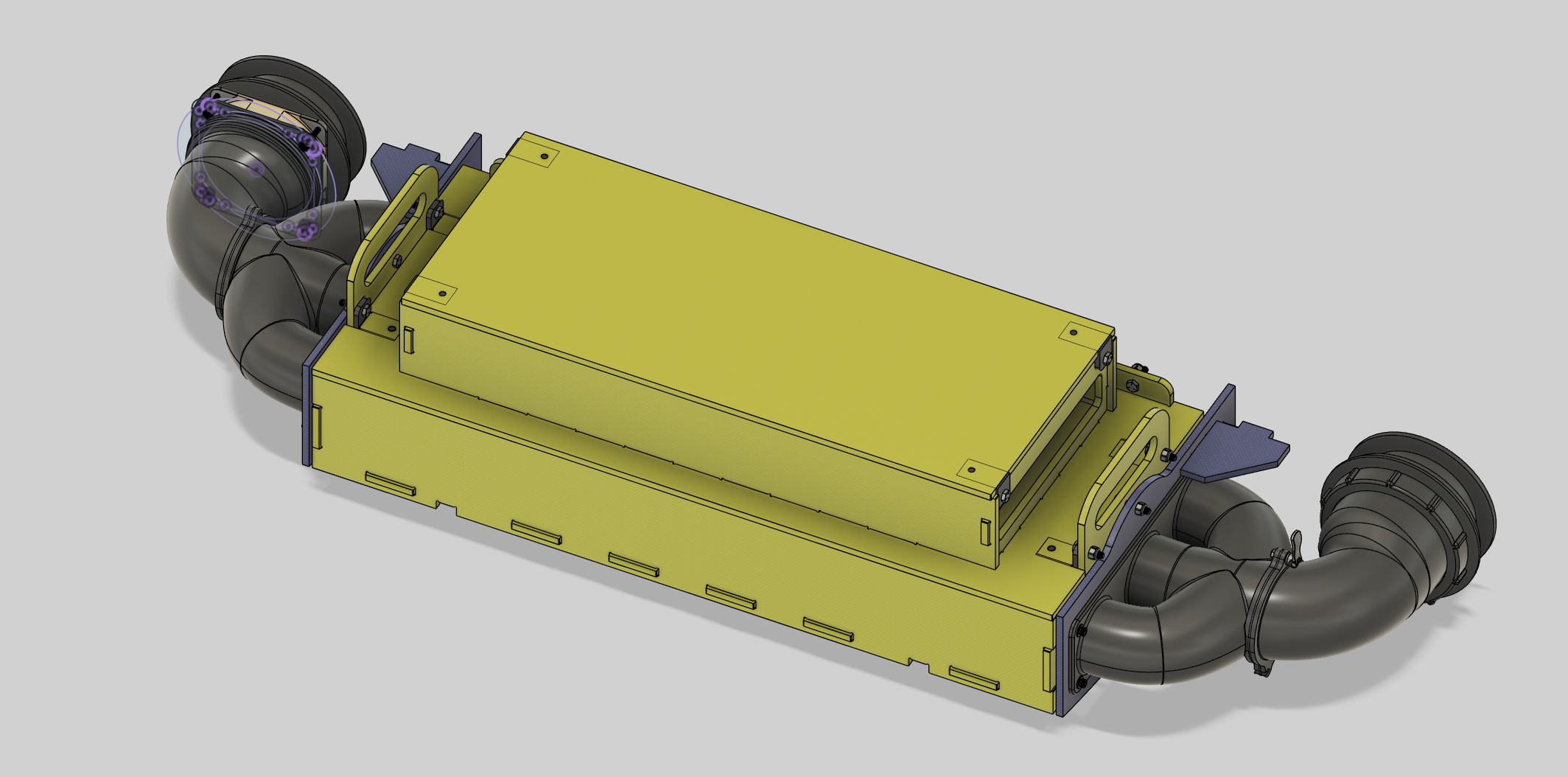

Final version featuring optimized surface modeling, integrated gasketing, and hardware mounting points.

Phase 4: Validation & Manufacturing#

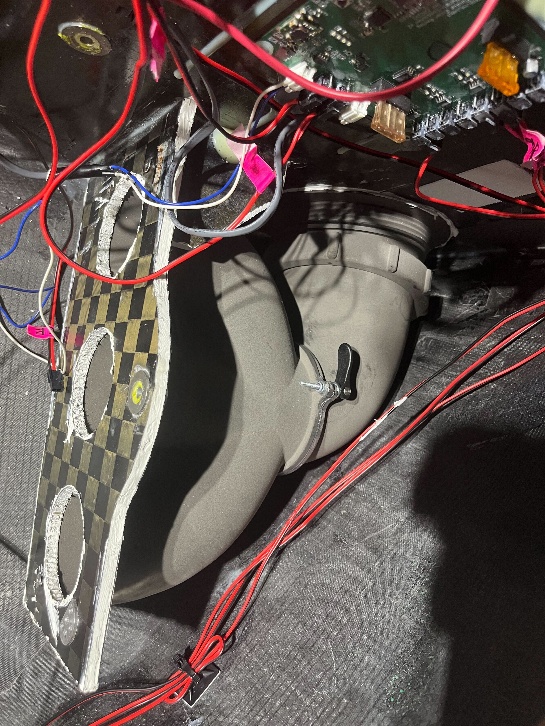

Full-scale FDM prototypes for fit validation before committing to final SLS manufacturing.

Final SLS-printed parts installed in the vehicle at competition. Silicone gaskets replaced initial design after judge feedback.

Results#

- 70+ design iterations over 2-month development cycle

- Installed and race-proven at competition

- Design feedback incorporated from competition performance

Key Skills#

- CAD: Autodesk Fusion360 (Advanced Surface and Solid Modeling)

- Manufacturing: SLS 3D Printing, FDM Prototyping

- Design: Design for Manufacturing (DFM), Iterative Development